One of Berlin’s former airports that closed in 2020, has reopened its doors as a sustainability and technology hub. In the space of Tegel’s former cargo halls, companies are working together to find solutions to dependence on fossil fuels.

The Berlin Energy Transition Dialogue conference welcomed climate curious visitors to the German capital this week. A mix of politicians and participants and companies working to help make Germany climate neutral by 2045 also attended. Euronews went behind the scenes before the conference to speak with some of those companies to see what the future could look like.

One of Berlin’s former airports that closed in 2020, has reopened its doors as a sustainability and technology hub. In the space of Tegel’s former cargo halls, companies are working together to find solutions to dependence on fossil fuels.

Marc Bernath, managing director of GUT Am Flughafen 1 said the pioneering project is one of the biggest development projects in Europe. Since the space became available one and a half years ago, 220 people already work at the former airport.

“Over the next few years, the city of the future is planned to be built and invented here. Currently, we are on-site with 17 different start-ups, developing the solutions that the city of the future needs,” he said.

GUT at Flughafen 1 oversees all the projects housed at Tegel and has worked hard to ensure as much of the original features are kept as possible, recycling and repurposing wood from the original terminal and luggage conveyor belts. Company CEOs, project managers and admin staff from all the projects unite at lunch to eat together, in the space that once was the international border between Germany and international territory.

How the future could look

The renewable city aims to create 20,000 jobs and have place for up to 5,000 workers to live on site. Bernath hopes the city will become a model for other cities in the world. Whilst the state hopes the city will be finished within 10-20 years, Bernath says the circular production park could already be ready in five years.

Also in the pipeline is a climate neutral brewery.

Bernath added: “Brewing beer is amongst the most energy-intensive of all food production. And that also needs to be decarbonised and made environmentally friendly so that we can still enjoy beer in the future.”

The company is cooperating with the company HH2E, which generates green energy at the former airport, enabling the brewery to brew green, environmentally friendly beer.

The HH2E project is working to transform societies’ dependence on fossil fuels by converting old coal and gas power stations to mix in hydrogen, wind and solar energy produced during the hours with the lowest prices for solar or wind energy.

“It involves injecting our hydrogen into either the natural gas network or the hydrogen network,” Gulnaz Badaeva, HH2E Project manager said.

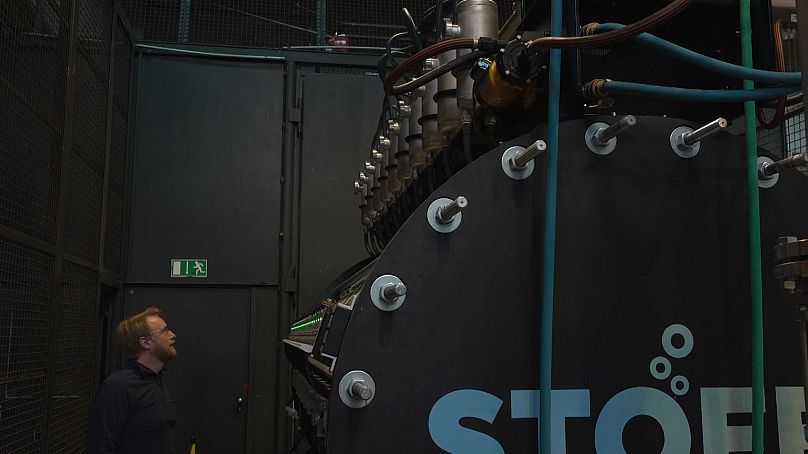

One of the major issues with wind and solar power is that storage can be very tricky to manage. But the Stoff2 project has been working on a solution and is working hand in hand with HH2E to provide a solution already.

Managing Director, Sebastian Sipp, says Germany has “three to four times” the amount of renewable energy that the company needs.

Sipp says the Stoff2 device stores the excess renewable energy from wind and solar in their device and releases it in a constant flow as green hydrogen, both as storage and an electrolyser. He hopes it will be used on a global scale, especially in the steel and cement industries.

“What our technology does, is it helps to decarbonise value chains, where electrons can't do the job,” Sipp said.

The technology is being rolled out to their first customer later this year.